- info@bola.world

- Customer Support :0086 (0553)-5628 068

- SUBSCRIBE

arbon fibre wheels offer two critical benefits for vehicle efficiency: 1.Reduced mass 2.Reduced rotational inertia Cost is often a major drawback. But does this have to be the case? Stock and after-sales carbon wheels are currently available for supercars, but they are simply too expensive for most vehicles to be justified. This gap in the market is exactly what Far-UK and the ACRIM consortium are looking to fill, helping carbon fibre wheels become commonplace and offering made to measure improvements for vehicle manufacturers and customers alike. With policymakers currently focused on lowering tailpipe emissions, automotive manufacturers need easy wins to improve the attraction to electric and hydrogen fuel cell vehicles. One of the main issues for uptake on electric vehicles is range anxiety. According to a survey by Kwik Fit, 35% of people have said they would not buy an electric vehicle as their next car because of this problem. Far-UK has been working alongside a consortium of industry-leading SMEs to produce the ACRIM (All-Composite Reduced Inertia Modular) wheel; a lightweight, low-cost and production-ready wheel. The ACRIM project, led by Carbon ThreeSixty, with resin suppliers Bitrez, robotic automation partner CNC Robotics and manufacturing supplier Composites Integration, are working to address the low-cost high-volume gap in the automotive market.

HOW DO YOU MAKE CARBON FIBRE WHEELS?

The concept developed over the 18-month programme investigated the most cost-effective way of producing both lightweight and low-cost composite components. A Far-UK BlackMetal™ Compression Moulded Centre (also known as forged carbon) was overmoulded by a Carbon ThreeSixty barrel during an RTM Process. Both processes utilise state of the art technology designed for medium to high volume production runs that are inherently automated, drastically reducing labour costs. Tom Higginbottom, Development Engineer at Carbon ThreeSixty, said: “The ability to drop an infinitely configurable wheel centre into Carbon ThreeSixty's Barrel Overmoulding Process, opens up many avenues for wheel modularity. Servicing a multitude of bespoke customer styled wheel centres through one modular Resin Transfer Moulding wheel tool, keeps up font tooling costs down and eliminates tool changeover time. Passing these cost savings onto customers, combined with un-sprung mass savings and improved NVH characteristics, carbon wheels become a very attractive offering for OEMs and the ever evolving EV market.”

SO HOW DOES ACRIM REDUCE COST?

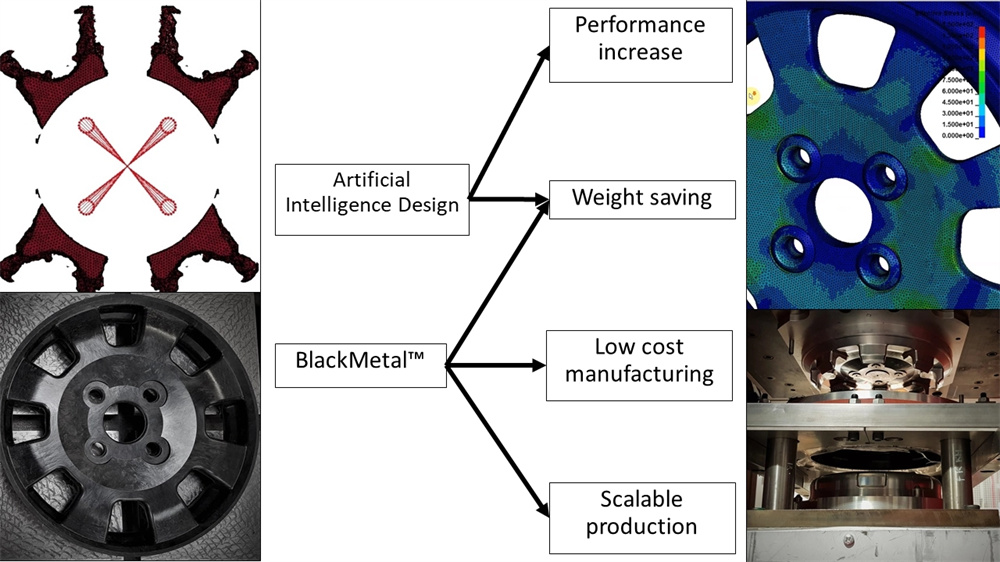

ACRIM is a carbon fibre wheel that takes advantage of the low-cost and low-weight manufacturing of BlackMetal™ whilst improving wheel performance. BlackMetal™ is a material solution Far-UK has been developing since 2014 to enable cost-effective, high-performance, and lightweight structures. It combines the manufacturing speed of press moulding, SMC (Sheet Moulding Compound) materials’ rapid processing times, and the low cost for high volume production. In collaboration with Far-UK’s Artificial Intelligence Design (AID) process, optimised structures were produced which furthered the components performance and understanding of the application of novel materials.

WHAT ARE THE BENEFITS OF LIGHTWEIGHT WHEELS?

Light weighting of all vehicle components is pivotal to improving range for all vehicles, as it requires less energy to accelerate the vehicle. It is estimated that just a 20kg reduction in a BEV’s weight (Battery Electric Vehicle) reduces in use C02 emissions by 120kg over 180k km. Specifically, on wheels, there is the additional benefit of reducing weight as it reduces rotational inertia. Rotational inertia describes how easy it is to rotate a mass. Depending on where mass is distributed, inertia varies. Similarly, the denser the material, the greater the inertia for the same shape. Some performance improvements can be noted in the reduction in un-sprung mass. This is the mass associated with everything attached to the lower side of the suspension. With a lesser un-sprung mass, the acceleration due to bumps is reduced, which reduces the forces on the suspension and the vehicle body and therefore improving ride comfort. Lighter wheels mean: • Less energy required for acceleration • Improved ride • Increased range • More opportunity for increased battery mass for further range improvement

HOW MUCH DOES THE ACRIM CARBON FIBRE WHEEL WEIGH?

The 13-inch ACRIM wheel is 44% lighter than an aluminium equivalent! The ACRIM wheel weighs 2.4kg, where the equivalent aluminium wheel weighed 5.4kg. Not only has the entire vehicle benefited from a reduction of 12kg, which is beneficial in its own right, but it has also reduced weight in a critical location, significantly improving vehicle range potential at a competitive cost.

Source: www.far-uk.com

WRITTEN BY HARRY DODGE - DEVELOPMENT ENGINEER